Over 15-year experience in producing high quality vertical machining and gantry type machining center.

Technical sales in MeganCNC provide 24/7 service, and they all have mechanical backgrounds and good oral English skills. They can easily understand clients' potential requirements and give them professional advice.

All engineers in MeganCNC have an average of 7 years of experience in producing, repairing, and maintenance for metal cutting machines.

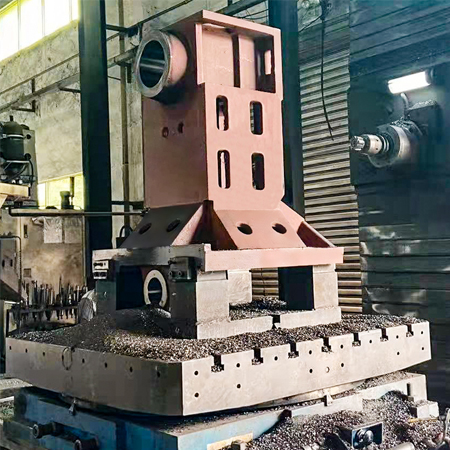

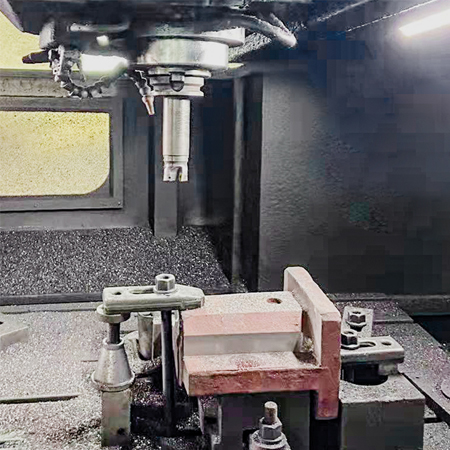

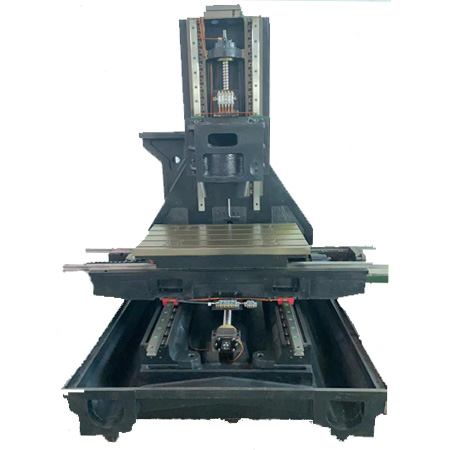

We design and process the machine casting In house, then assemble the machine body till we finish the complete machine.

MeganCNC has a spare parts warehouse that is always ready for easy-broken spare parts. MeganCNC promises to transport the parts in 24 hours on a cost and time-saving solution to the clients.

Table Size: 1000*500mm, X/Y/Z travel: 800*500*500mm

Table Size: 950*600mm, X/Y/Z travel: 800*600*600mm

Table size: 1200*600mm,X/Y/Z travel: 1100*600*600mm

DRV-1513 Table Size:1700*1200mm, X/Y/Z travel: 1600/1300/800mm

DRV-2015 Table size: 2100*1200mm, X/Y/Z travel: 2000*1500*800mm

Our machines find its position in the application of mold tooling and variety metal parts processing. Plastic injection mold, die casting mold, forging dies, shell castings, pattern making and blow mold are most suitable to our vertical machining centers. Metal like steel, stainless steel, Aluminum, Iron and other material processing cannot be finished without our machines. Covering a wide range of industries including jig fixture, automatic parts, gym device parts, automobile parts, and medical parts etc.

MeganCNC produces the machine by raw casting, assembling, and strict quality control.

All the raw casting should be stocked over 6months in our Dongguan factory, and then we produce them according to the monthly production plan.

After painting, we start to do the machine body assembling.

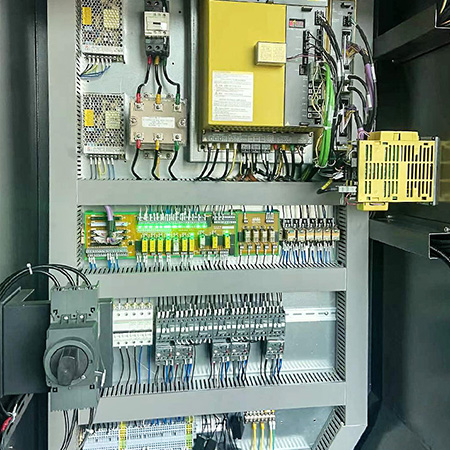

We do the assembling of the spindle, electrical cabinets, tool magazine, and machine cover

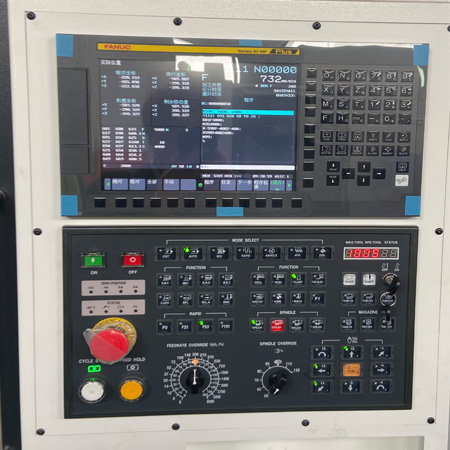

We start to adjust this machine including, 48hours running, and PLC adjusting, and other accessories like the 4th axis installation.

MeganCNC is a mature CNC machine supplier in Dongguan city. Registered in 2013 in Hong Kong, we offer a variety of innovative and technologically advanced metal cutting machines, CNC machine tools such as CNC lathes, machining centers, drill centers, and other manual machines. Machine tools production, long our specialty, supports all other product developments. Although our product line continually changes in keeping with the times, our energetic spirit remains ever-strong, ever open to the future.We provide superior customer service and our experienced engineers are able to provide feasible solution for any specific application within 24 hours.

If you don’t know which machine is suitable send us the parts drawing and let us know the demand, then we’ll prepare the basic specification and price list.

Customers check the specifications, and we double check that the machine’s functionality meets their requirements.

advance the machine specially,we go to price negotiation,then we sign the PI or contract to confirm, and the client makes deposit.

We will show the video of the machine’s production. If the client cannot be present in person, we will provide the test reports and the video of how the machine works.

The clients pay the balance payment, and we will pack and ship the machine.

When the clients receive the machines, we will have a video call and guide them on how to unpack and install the machine.

Megancnc HK company is registered in 2013.

CNC milling machine factory is built in 2014 in Dongguan.

CNC lathe machine factory is invested with Taiwan engineer in 2016 in Dongguan.

Megan shenzhen trading company is registed in 2018.

© 2022 MeganCNC All rights reserved.