1

With a Different 4th Axis, you can perform different metal machining. You can either choose a Horizontal or Vertical Rotary Table, which depends on the machining parts.

2

Working with a 4th Axis CNC Milling Machine will save your working time a lot. You can program all the machining steps by doing the one-time loading and fixing. It greatly increases your working efficiency.

3

A 4th Axis CNC controller is little different from 3 Axes. It has 4th servo motor and driver. It is also from FANUC/MITSUBISHI/SIEMENS, depends on your decision.

4

Since you need just load and fix the part once, it avoids the tolerance caused by second loading and fixing. The machining accuracy could be assured.

Our products will last for 10+ years, and the price we offered is matched with our high-quality CNC machines.

You can use different materials to build your molds, applied for medical, customer electronic industries etc.

You can also get some technical guidance our user manual, and download our maintenance plan.

A CNC router is mostly for wood cutting or soft metal material cutting. It can be used as DIY machine. However, 3 axis CNC mill is an professional industrial machine. It mainly used on all kinds of metal cutting, and it can perform more complicated workpiece processing.

To install a 3 axis CNC mill, you have to prepare:

1.Full Enough Space

You will get the machine size from the CNC mill machine supplier, take the size and plus 500mm more, it is the machine setting up space.

2.Solid floor without vibration, radiation or fire

Your CNC mill should be far away from the vibration place. A vibration origin like punching machine, press machine etc. should also be far away from the 3 axis CNC mill.

Radiation might hurt the servo motor and driven, even cause damage to operator, so it should be limited to close this machine.

And your floor should be solid not a mud or the concrete which is not fully dry. It will affect machines accuracy.

3.Stable voltage

If external merit is not stable, or if your plant is on the high peak, please use a voltage stabilizer in case the voltage breaks during machine running.

4.Air Compressor

You must have set up the air pipe at the beginning of your factory’s set up. Be sure that the air is filtered. and air pressure is6-8kgf/cm2

5.Machine Setting Up

Double check the voltage of the 3 axis CNC mill with your external voltage, check with your machine supplier about how to connect the electric wire.

Put a leveler on the working table, and adjust the leveling bolt to make sure that the CNC machine is in a horizontal level.

Fill in the cutting fluid to the chip tray, and connect the air.

Start the spindle slowly from 0 to 500, then to 1000, 2000RPM, warm up the machine around 10 min. and then higher.

Start the tool magazine, change the tool without loading to make sure the sequence is correct.

6.Load the tool and start processing

Load the right tool inside tool magazine, and load the workpiece with fitable clampture, lock them closely, and the machine could be started.

To extend a 3 axis CNC mill’s life, you have to maintain it every day/ every week/ every month.

1.Do read the operation manual before operation

Your operator should know every button’s action, and the operator should follow the DO and DO NOT things in our manual.

2.Do the maintenance work according to the operation manual.

3.Stop the machine immediately if you find

A. Some noise coming up spindle/ 3 axes motor/ electric cabinet or other places

B. 3 axes moving speed is out of control

C. Some button is broken or invalid

D. The door and window are open or broken

E. The tool is broken

F. Some function is not working

Contact the machine seller to seek help

4.Check the machine accuracy every 6month

If the machine moving axis is hit, check the machine accuracy immediately, contact the machine supplier in case cause you more loss.

5.Do clean the machining chips every day and lubricate it every day.

If you are do the CNC machining, it will generate lots of chips. Clean it every day in case the small chips go into the ball screw and slideway.

Check the oil pump, make sure there is enough oil.

6.Use proper parameter to do machining

Do not heavy cut the hard material with higher spindle speed or higher moving speed. This will cause damage to spindle and servo motor, and the cutting tools are easily broken as well.

Generally speaking, a spindle is vital part for the 3 axis CNC mill. And its repair cost is higher too. Its speed is 6000RPM, 8000RPM, 10000RPM, 12000RPM,15000RPM, 18000RPM, 20000RPM and 24000RPM, and there are belt connection, direct connection.

6000RPM spindle is mechanic gear type, which is mostly used on the heavy cut.

There are FANUC, MITSUBISHI, SIEMENS, GSK in our products. But FAGOR, HEIDENHAIN are also famous controller. But in China, these controllers are not that popular.

Most popular CNC controller are FANUC 0i MF, MITSUBISHI M80A M80B, SIEMENS 828D 848D, GSK25Mib etc.

A 3 axis CNC mill cost could be divided into serval parts, which are: Machine body, CNC controller, Tool Magazine, CNC Spindle, Other Assistant part and Management Cost.

Machine Body Cost

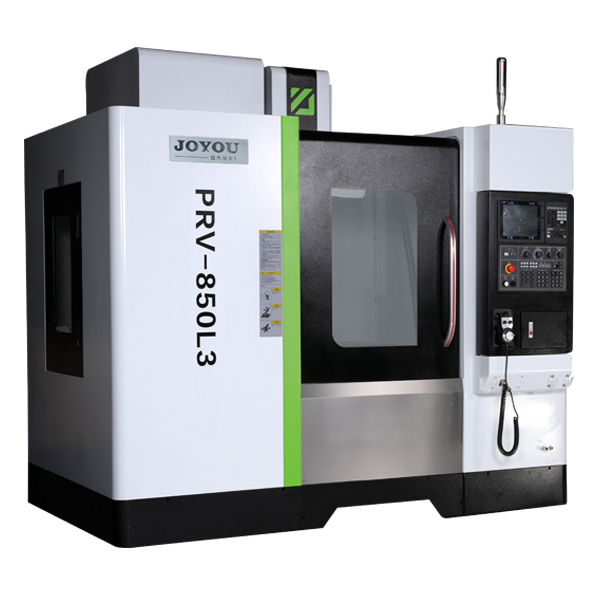

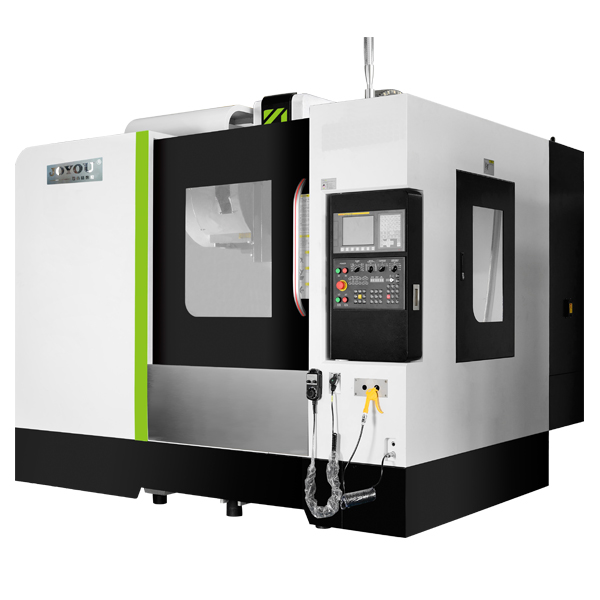

Machine body is built by the iron cast, normally HT250, HT300 are the popular brand. The iron are melt into rough machine body parts separately, like saddle, slideway, ram, spindle box etc. All these parts needs to do CNC machining according to requirement. And then assemble them into a basic machine body like below. For a buyer, just to check the machine’s weight.

Especially for 800*500 model, the weight of the machine ranges from 3000KG to 5000KG. it make a big difference in price and quality stability.

CNC Controller

This part is just an heart to a 3 axis CNC Mill. Generally Speaking, over 90% CNC Mill supplier will cooperate with one brand mostly, and take 2 other brands as auxiliary. In China, FANUC and MITSUBISHI are most popular ones. But FANUC controller would be little higher than MITSUBISHI on average. SIEMENS 828D has near same cost as MITSUBISHI M80B. but SIEMENS 848D will be more expensive. GSK is most cost-saving. If you want to know more about the controller, contact us please.

Tool Magazine

For a 3 axis CNC milling machine, Arm type tool magazine and Umbrella type tool magazine.

Arm type tool magazine 24T, 30T, umbrella type tool magazine with 20T are common optional accessories.

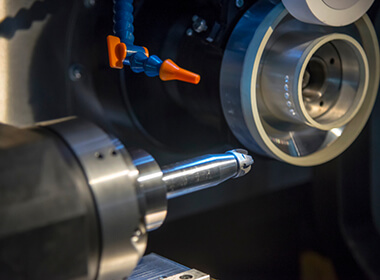

CNC Spindle

China CNC machine supplier use spindle from Taiwan a lot. Its spindle are belt connection with 8000RPM/10000RPM, or direct connection with 12000RPM/15000RPM.

Low spindle speed cost is cheaper, but direct connection has a faster speed to fast the efficiency.

Now electrical spindle is also under developing, its spindle speed could reach up to 18000RPM, 20000RPM, even 24000RPM.

Auxiliary Parts

Auxiliary parts contains metal cover, electrical components, heat exchanger, coolant system etc. it won’t make big difference unless they have a very eye-attractive design for the metal cover.

Management Cost

A well management company will have a strict and complete operation system. The good management will save company’s cost and generate good and stable quality products.

You might ask, how to know if a company is a well-managed one?

Check their departments allocation,

Check their production record.

Check their quality record

Check compliant record.

After knowing this cost summary, then you can know how to compare a CNC milling machine’s price.